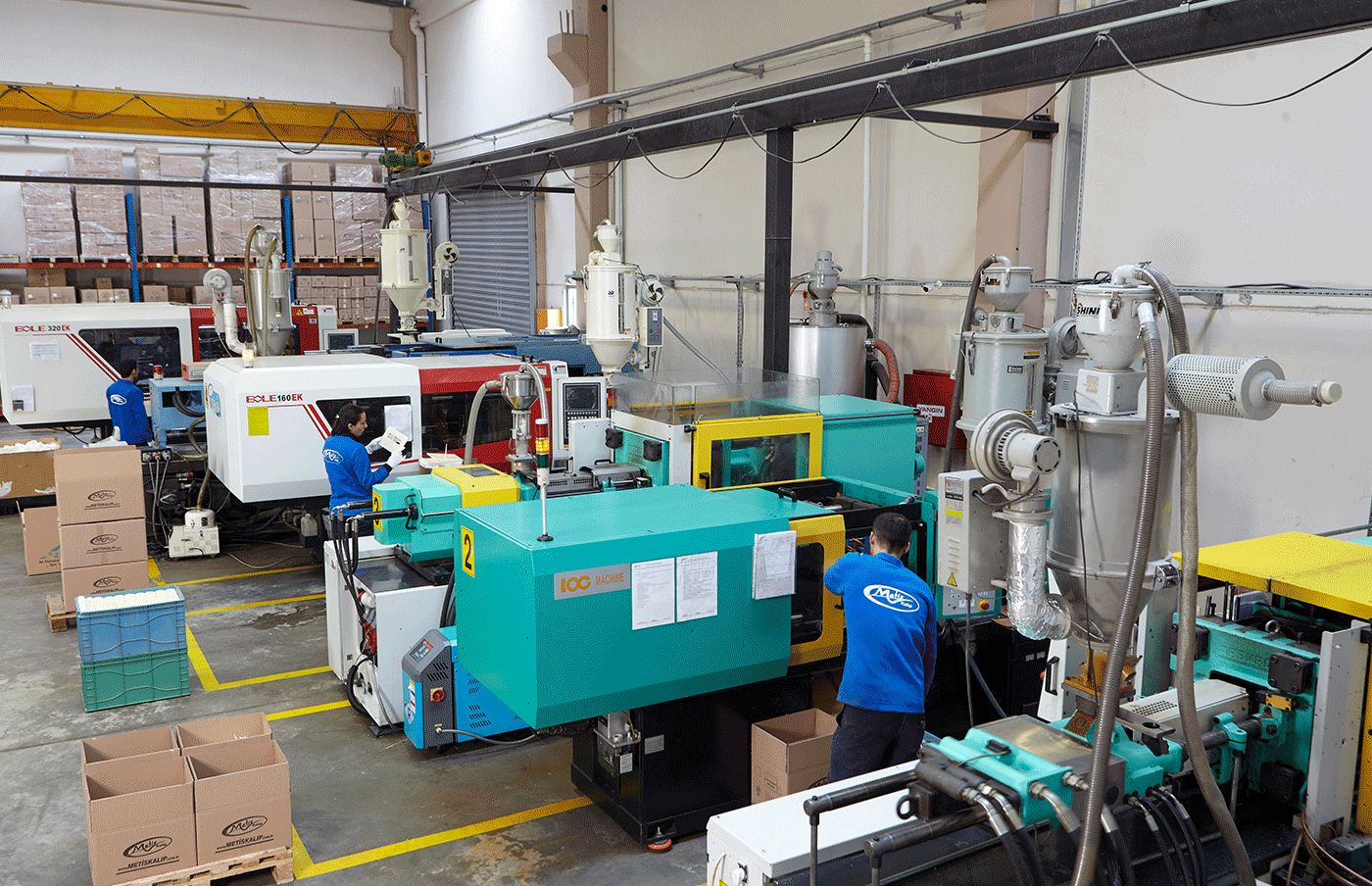

Metis Kalıp was founded in 2005 in a 350 m2 workshop in Pınarbaşı, İzmir. It proceeded with sound steps and moved to a factory of 850 m2 in 2011 in order to meet the needs in line with its objectives. Today, its 2.500 m2 factory in Manisa continues to provide service to all parts of the World with a team of 25 experts who know that their knowledge is increased as they share, with the philosophy of “ Share to Knowledge”.

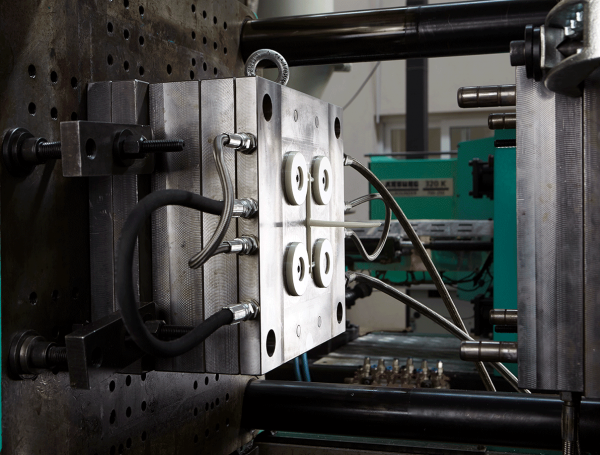

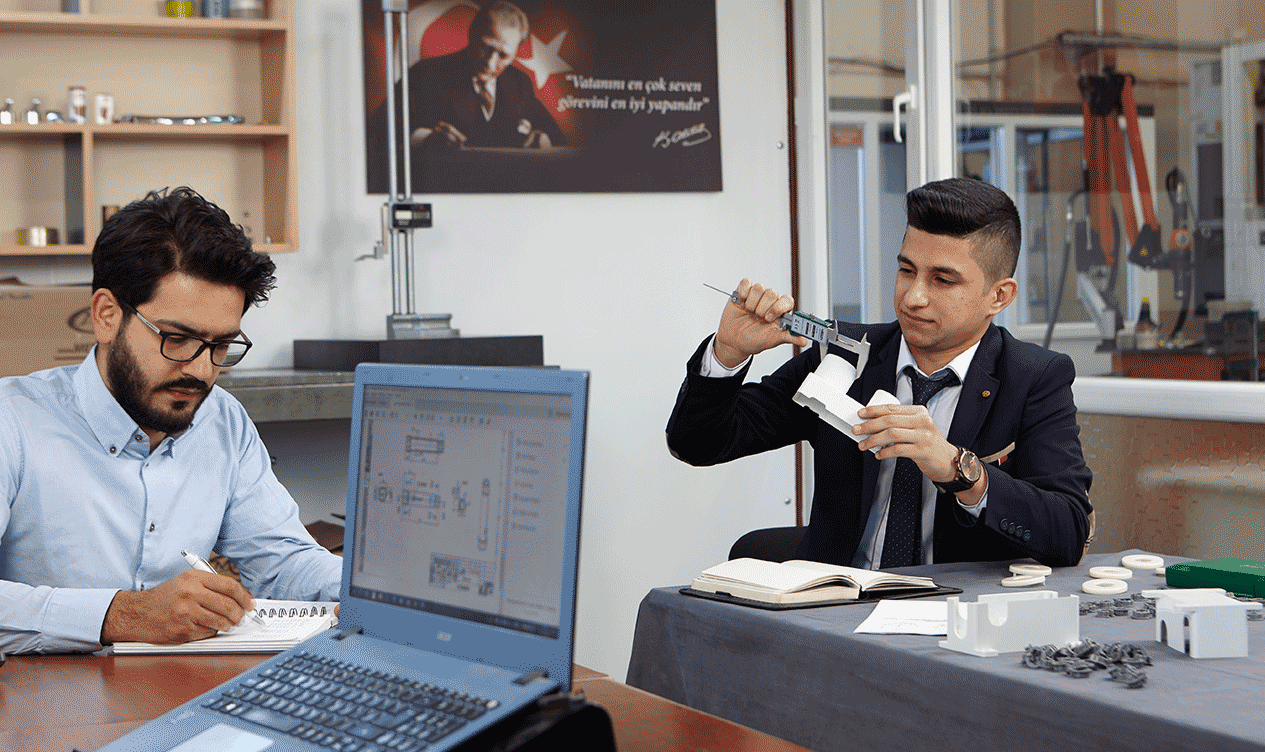

Metis Kalıp, which meticulously plans and designs every stage of plastic injection molding for about 13 years and produces with a precision up to the micron level and in all these processes, gives approval for shipping after the assurance of the quality of the products by applying effective “Quality Assurance” procedures.

2.500 Square Meters Factory Area

Metis Kalıp was founded in 2005 in a 350 m2 workshop in Pınarbaşı, İzmir. It proceeded with sound steps and moved to a factory of 850 m2 in 2011 in order to meet the needs in line with its objectives. Today, its 2.500 m2 factory in Manisa continues to provide service to all parts of the World with a team of 25 experts who know that their knowledge is increased as they share, with the philosophy of “ Share the Knowledge”.

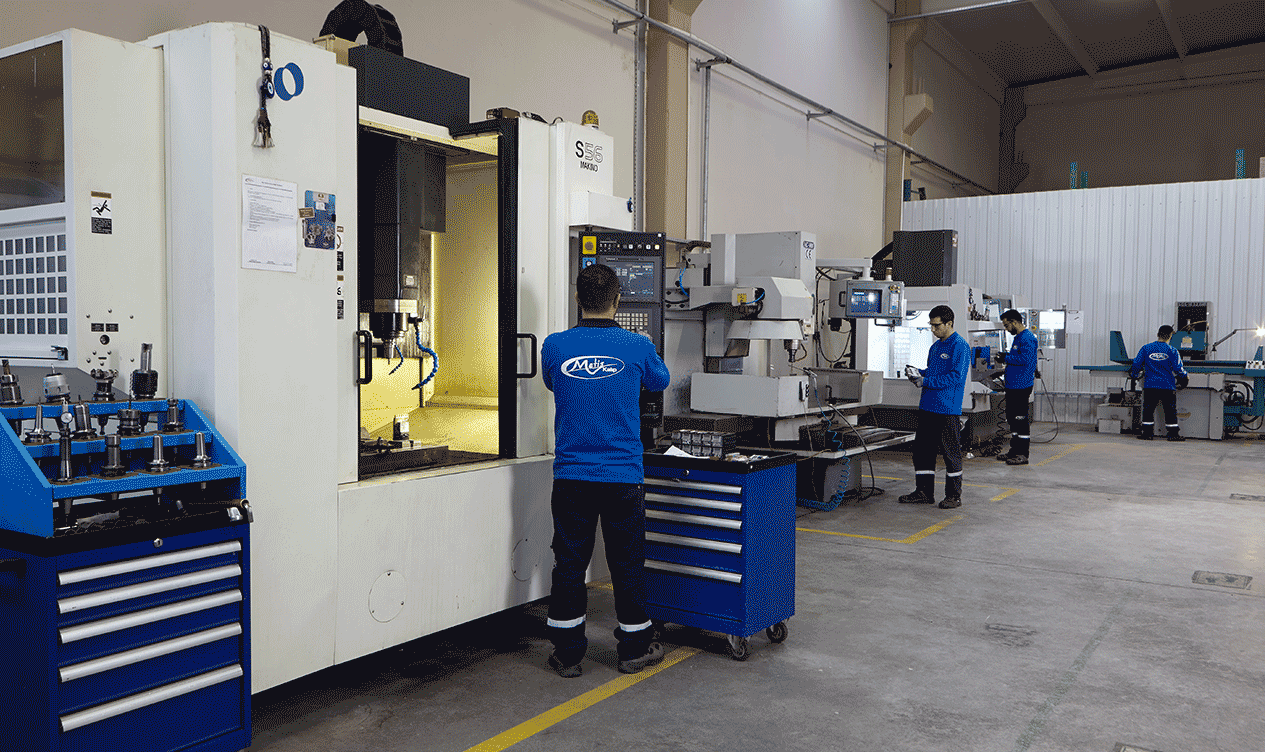

0,05 mm Precision Production

Metis Kalıp performs all the design and production process by using Professional simulation software. It makes mold designs to produce plastic injection products from 0.05 g to 977 g. it finalizes the design process by producing a fully functional prototype according to customer demands.

The Biggest Investment: Value to the Environment

Metis Kalıp proves its sensitivity to the environment by not leaving waste materials behind after production. Recycling waste materials in cooperation with contracted companies, Metis makes the biggest investment in the environment, i.e. the future.

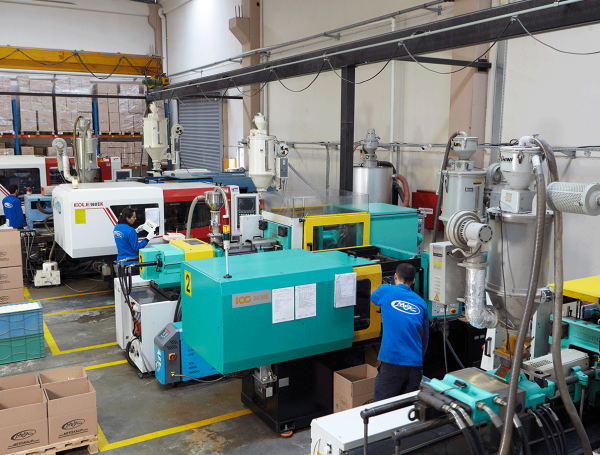

700.000 Units of Daily Production Capacity

While completing the production of the mold in the mold section where the latest technology machines, in the injection section, prepares the final product using dozens of raw materials such as ABS, PC, PA, PPA, PCABS, PPO, PBT, POM, PP, PP+EPDM, ASA.

Metis makes periodic mold maintenance with systematic approach and responds to customer demands in the best way. It continues to be one of the best in the sector with its daily production capacity exceeding 700.000.

%100 Customer Satisfaction

Metis checks in detail each of the completed molds, critical dimensions, whether they are within tolerances. If everything is correct and the first molded products have not failed, the first sample is delivered to the customer. Products are tested twice before and after production.

Metis, which knows very well that the service with different point of view has a big advantage, gives infinite warranty to its customers in all molds. Instead of a long-lasting product, it offers solutions rather than products with the objective of an immortal product.

- Metis Kalıp Introduction

- How It’s Making?